Melting process is carried out by 2 crucibles by dual track induction melting furnaces with continues monitoring melting process by Pyrometers and Spectrometer.The most commonly used melting system is the induction crucible furnace. The induction crucible furnace has a crucible which heated by an induction furnace coil surrounding the crucible.

Furnaces : 2Nos

Capacity : 300Kg/Each

Melting Capacity : 250 tons/month

Proof machining is an important step in the manufacturing of cylinder liners as it helps to ensure that the final product meets the required dimensions and tolerances. By verifying the dimensions before proceeding with final machining, manufacturers can save time and materials by avoiding the need for costly rework.

Our machine shop is well equipped with cnc & spm machine, along with heavy duty latch machines. Rough & semi finish machining done by heavy duty lath machine and fully finish is done by cnc machine to give high accuracy in dimensional parameters, surface roughness & geometric parameters. We are also having SPM for Outside & Bore machining combine operation.

In final inspection we maintain & checked all parameter as per standard drawing. We have digital micrometers, digital vernier , boregauge, roundnesstester & pneumatic plug gauge, pneumatic ring gauge which fullfill the final inspection criteria.

Our final inspection departments is well experience and well equipped by all instruments. It consists of inspection the surface of the casting with naked eye or sometimes with a magnifying glass or microscope.

It can only indicate surface defects such as blow holes, fusion, swells and external cracks. almost all castings are subjected to certain degree of visual inspection.

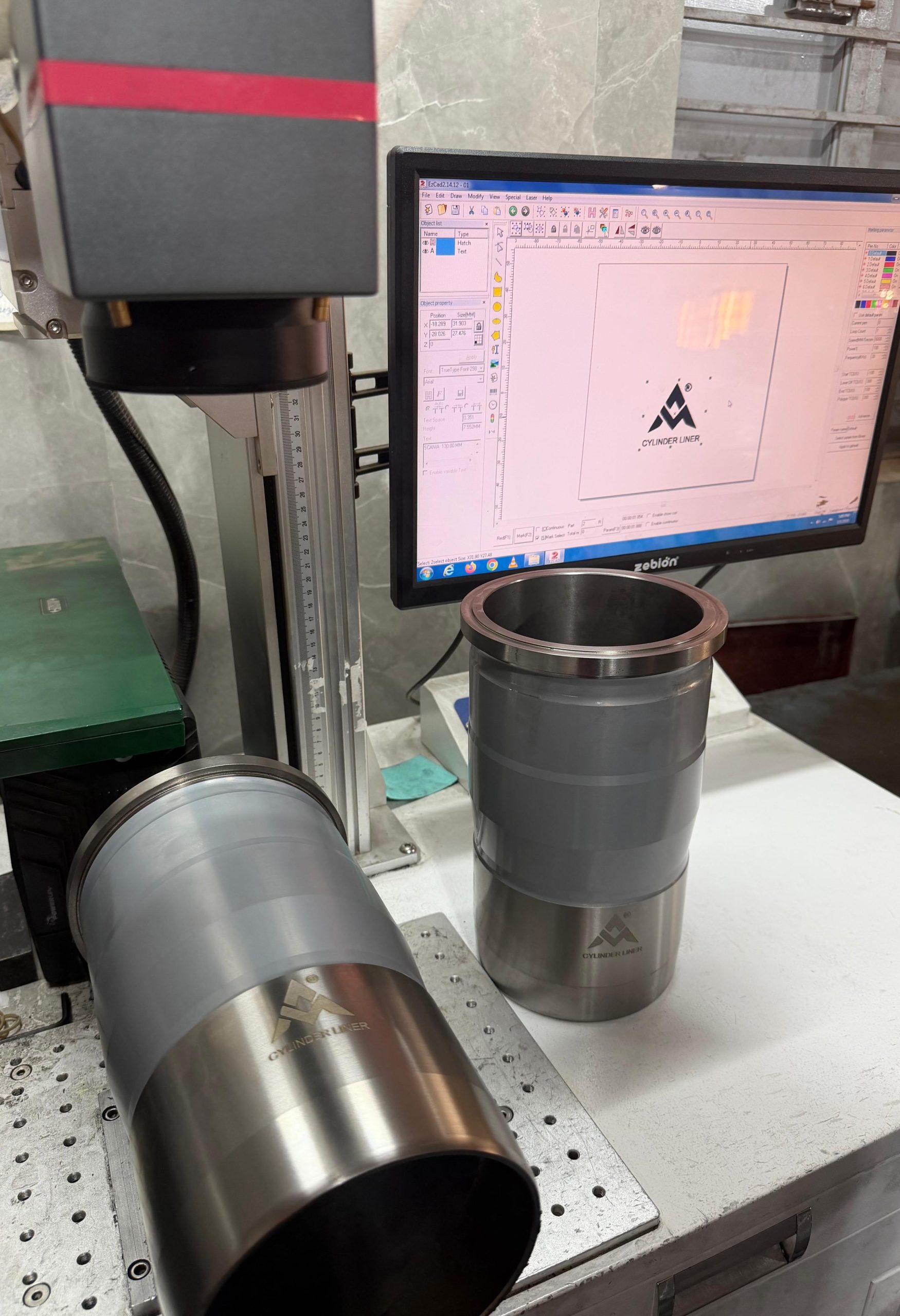

We have laser marking machine for traceability and mark the logo. Neat, clean & indelible markings of logos & part no. Are marked which doesn’t produce stress or change in physical properties of materials. Marking are proof from chemicals, water, oil, grease and other fuels.

Our machine have higly accurate and presice marking capability.

Cleaning machine to clean the cylinder liners and sleeves before the packing. Finish cylinder liners are duly oiled & placed in vci paper and packed in corrugated box as per customer requirements.

Safe, quick and undamaged – that’s how our products reach any destination all round the world.

To assure comprehensive quality methods that prevent damage in transit, because what matters is to deliver the components safely to the end user in the quality in which Maan Auto motive produced for them.